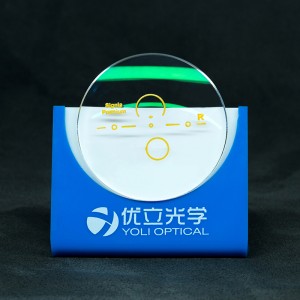

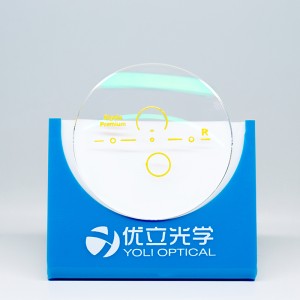

1.49 CR39 Semi-finished Spectacle Lens Blanks

What Semi Finished Lens Blanks Can do?

Spectacle lenses production units that transform semi-finished lenses into finished lenses according the precise characteristics of a prescription.

The customization work of laboratories enables us to provide a wide variation of optical combinations for wearer needs, especially as regards the correction of presbyopia. Laboratories are responsible for surfacing (grinding and polishing) and coating (coloring, anti-scratch, anti-reflective, anti-smudge etc.) the lenses.

Why to Choose CR-39 Optical Lenses?

Crystal Vision (CR) are top quality lenses made by one of the world’s largest lens company.

CR-39, or allyl diglycol carbonate (ADC), is a plastic polymer commonly used in the manufacture of eyeglass lenses.

The abbreviation stands for “Columbia Resin #39”, which was the 39th formula of a thermosetting plastic developed by the Columbia Resins project in 1940.

Owned by PPG, this material is revolutionising lens making.

Half as heavy as glass, far less likely to shatter, and optical quality nearly as good as glass.

CR-39 is heated and poured into optical quality glass moulds – adapting the qualities of glass very closely.

a) Economic

b) Light

c) Shatter resistant

d) Can be tinted & coated

e) UV protection

What is a freeform lens?

A freeform lens normally has a spherical front surface and a complex, three-dimensional back surface which incorporates the patient’s prescription. In the case of a freeform progressive lens, the back surface geometry includes the progressive design.

The freeform process utilises semi-finished spherical lenses which are readily available in a wide range of base curves and indices. These lenses are accurately machined on the back side using state-of-the-art generating and polishing equipment to create the exact prescription surface.

• the front surface is a simple spherical surface

• the back surface is a complex three-dimensional surface

Technology for freeform lenses

• Provides the flexibility to offer a wider range of high level products, even for the smaller optical laboratory

• Only requires a stock of semi-finished spheres in each material from any quality source

• Lab management is simplified with significantly fewer SKUs

• Progressive surface is closer to the eye - providing broader fields of view in the corridor and reading area

• Accurately reproduces the intended progressive design

• Prescription accuracy is not limited by the tooling steps available in the laboratory

• Accurate prescription alignment is guaranteed