Wholesale Progressive Photochromic Lenses Factory – 1.67 Spin Coat Photochromic – YOLI

Wholesale Progressive Photochromic Lenses Factory – 1.67 Spin Coat Photochromic – YOLI Detail:

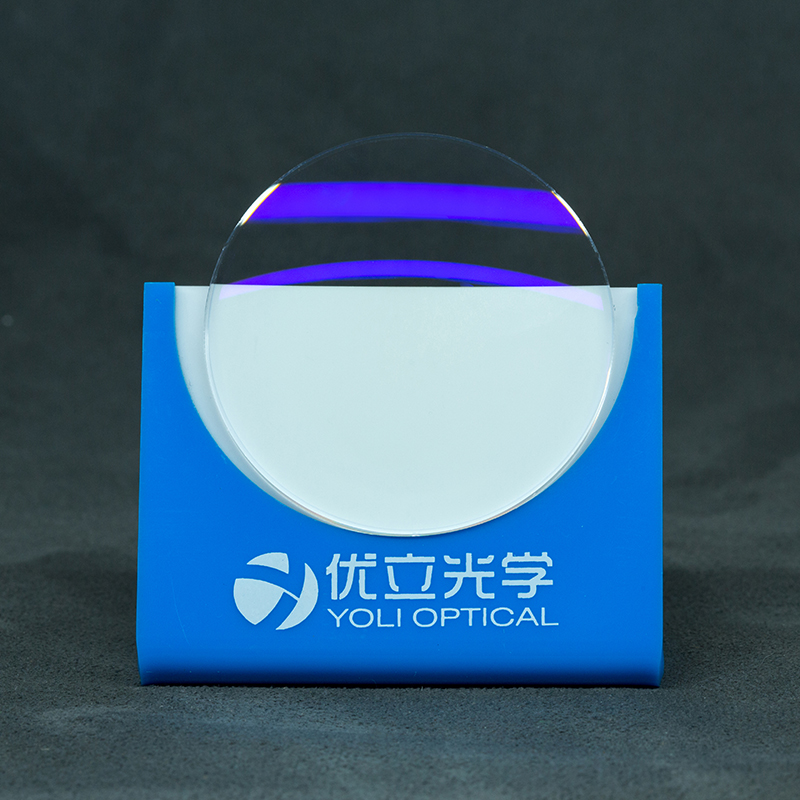

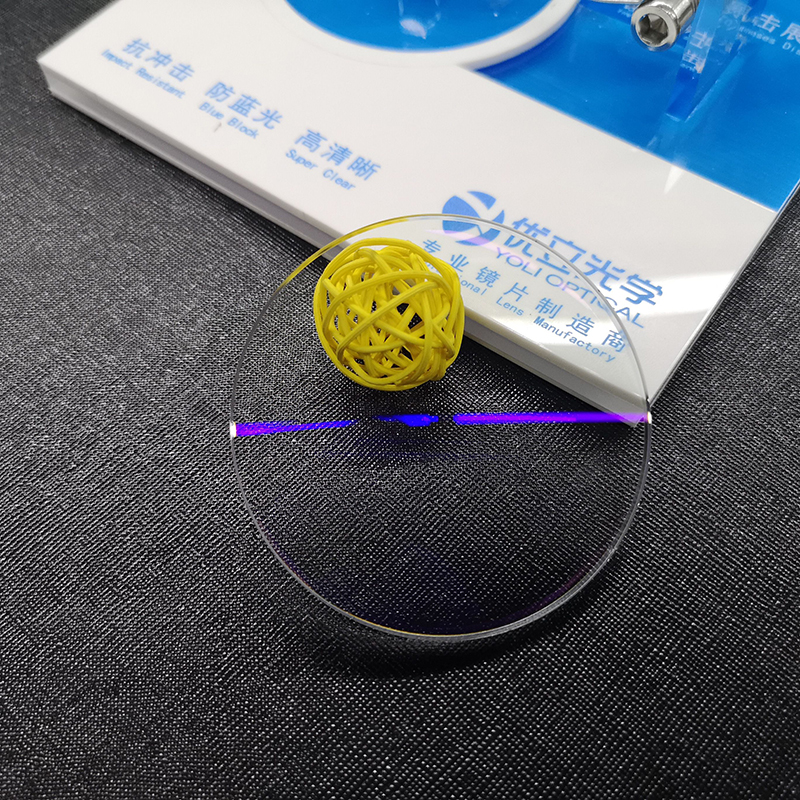

The Photochromic Spin Coat Technology

Spin coating technique is used for making a thin coating on relatively flat substrates. The solution of material to be coated is deposited onto the substrate which is spun off at a high velocity in a range of 1000-8000 rpm and leaving a uniform layer.

Spin-coating technology makes the photochromic coating on the surface of lens, so color only changes on lenses surface, while in-mass technology make the whole lens change color.

Why Need Photochromic Lenses?

With the time change and the arrival of spring, our hours of sun exposure increase. Purchasing sunglasses is therefore essential to properly protect yourself against UV rays. However, lugging two pairs of glasses around can be annoying. That’s why there are photochromic lenses!

This type of lenses is ideal for the different levels of light both inside and outside. Photochromic lenses are clear lenses that react to ultraviolet rays. They therefore possess the ability to change colours depending on the light

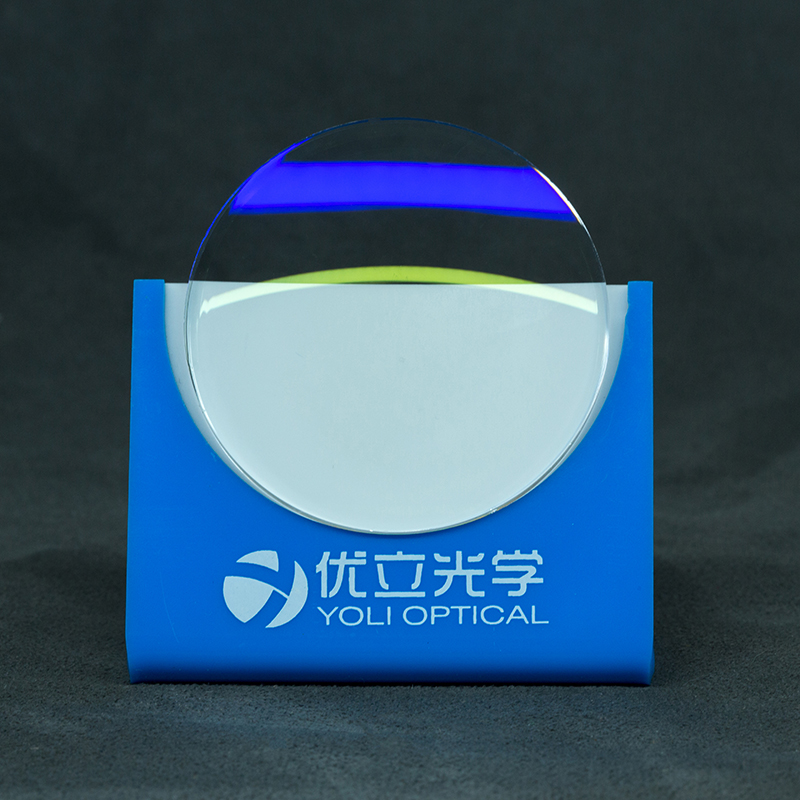

Protect Eyes With Blue Block Lens

Blue light is visible light with high energy in the range of 380 nanometers to 495 nanometers. This type of lens is designed to allow good blue light to pass through to help you, and at the same time prevent harmful blue light from passing through to your eyes.

Anti-blue light lenses can immediately reduce symptoms of digital eye strain, especially when working at night. Over time, wearing blue blockers while working on digital devices may help to normalize your circadian rhythm and risk of macular degeneration.

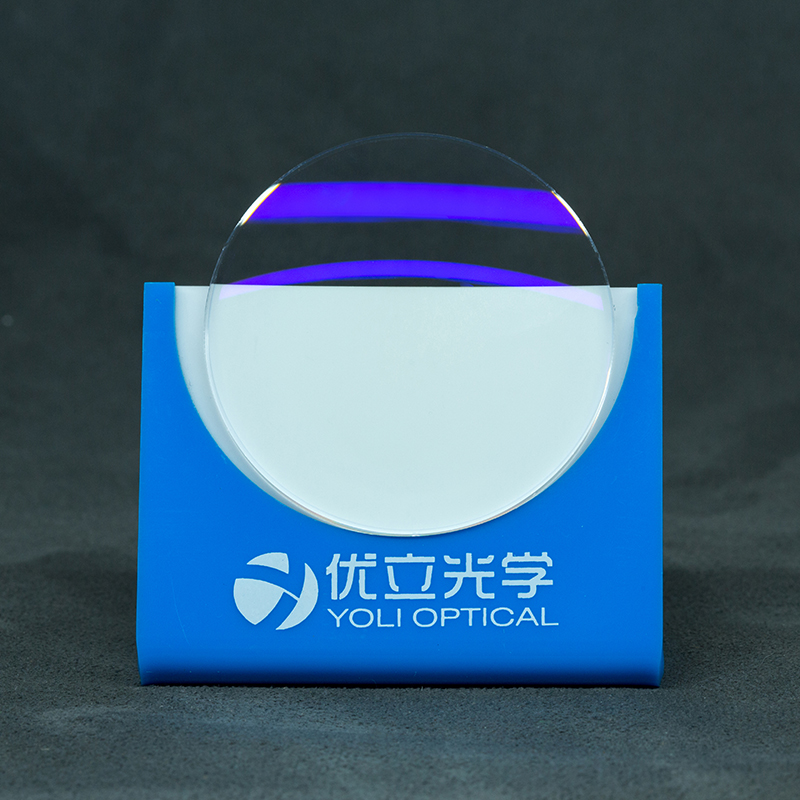

Advantages of 1.67 Material

High index 1.67 Single Vision lenses can be great for stronger prescriptions because they’re thin and light instead of thick and bulky. The 1.67 high-index lens material is a great choice for prescriptions between +/-6.00 and +/-8.00 sphere and above 3.00 cylinder. These lenses provide nice, sharp optics and a super thin appearance, and they work well for drill-mount frames when the prescription is too strong for middle index lens.

Product detail pictures:

Related Product Guide:

Fast and superior quotations, informed advisers to help you choose the correct merchandise that suits all your requirements, a short generation time, responsible quality control and different services for paying and shipping affairs for Wholesale Progressive Photochromic Lenses Factory – 1.67 Spin Coat Photochromic – YOLI , The product will supply to all over the world, such as: Jakarta, Jordan, Serbia, For more than ten years experience in this filed, our company has gained high reputation from home and abroad. So we welcome friends from all over the world to come and contact us, not only for business, but also for friendship.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.